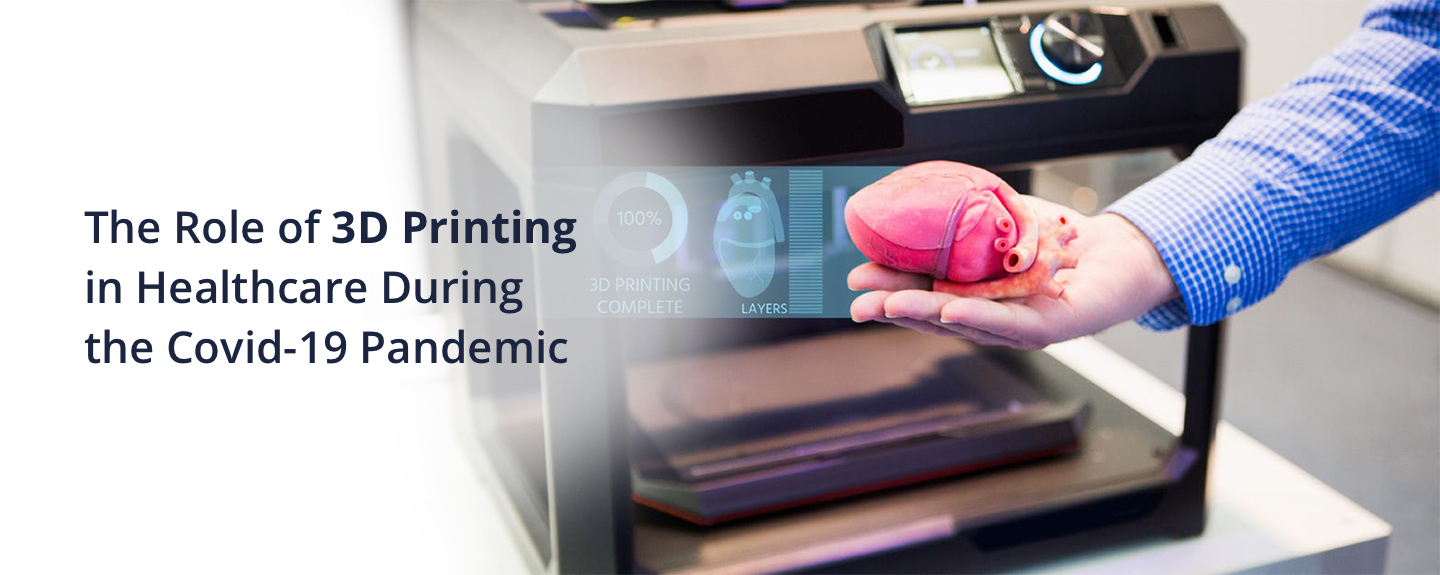

The Role of 3D Printing in Healthcare During the Covid-19 Pandemic

Over the last few months, the pandemic Covid-19 has posed several challenges on the global healthcare system. There has been a consistent spike in the demand for Personal Protective Equipment (PPE), hospital beds and various other essential medical products. With the period of time, public health emergency has also had a great impact on the global supply chain as lack of raw materials and social distancing protocols have restricted access to these products. This has resulted in the global shortage of medical devices that are extremely important to the global healthcare system’s response to Covid-19.

Harnessing the advantages of 3D printing technology

Using the 3D printing technology to manufacture medical products could help overcome these challenges on a global platform. Since the beginning of the pandemic, the 3D printing technology has been used to manufacture different kind of medical devices like masks, face shields, ventilators and different tools and devices that are required for swab and other kind of testing. With the help of this technology, healthcare workers have been able to fill the production gap on a large scale. Unlike the rest of the medical device manufacturing that takes place in centralized facilities, 3D printers being portable, can be transported to any location and at different sites which include the hospital itself. This implies that supply will never shut down if the access to a particular manufacturing plant has been cut down due to the Covid-19 regulations. In addition to the benefit of mobility and portability, 3D printer’s supply chain is different when compared to that of the traditionally manufactured tools and equipment. This indicates that raw materials will now be easier to acquire and procure. Different health agencies across the world, along with the Food and Drug Administration has taken a lot of steps to support the contribution of this technology during the pandemic. There are even systems in place through which individuals can now upload their digital design files that have the specifications that the 3D printers will follow. 3D printing also is considered an efficient manufacturing process when it comes to keeping up with the demand for nasopharyngeal swabs and other testing tools.

The mass customization capability of the 3D printing technology has all the more benefitted the medical sector. 3D printed masks that offer an ergonomic fit are the need of the hour and have been in great demand during the difficult times of the pandemic. Apart from manufacturing 3D printed devices and tools for the medical industry, the 3D printing technology is also used to offer training and visualization facilities to the healthcare workers so that they are able to cope up with the limited pool of trained resources. The ability of this technology to replicate the human anatomy gives healthcare professionals the freedom to get a hands-on experience especially during the times of the pandemic like the Covid-19. The 3D printed mannequins are often printed with the help of transparent materials so that the internal parts like the nasal and throat areas are revealed and trainers can clearly demonstrate the special instructions so that discomfort in patients can be minimised.

3D printing has also been used to fabricate temporary dwellings in the emergency wards with the purpose of isolating people who are in quarantine. Therefore, during the times of the Covid-19 emergency, 3D printing has emerged as an important technology to support advanced healthcare and to elevate general response towards emergency. It is this crisis that has highlighted how this technology can be a driving force towards creating an environment friendly future. Digitization is expected to continue to transform the 3D printing machines into key components of the Internet of Things and Industry 4.0 environments in the post pandemic era.